CRUSHERsurf

Multiscale analysis and modeling of rock crusher wear morphology

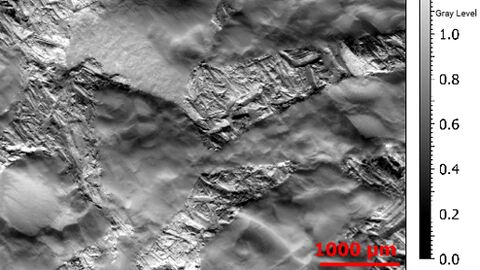

The aim of this research project (see figure 1.) is to build a methodology to characterize the wear of a rock crusher taken as a system as a whole ("system wear") from a local in situ measurement of a metal/ceramic (CMM) insert ("macroscopic wear")

.This wear is then related to the elemental wear of a surface representative of CMM damage ("mesoscopic wear") using in situ and laboratory defective and topographic methods. Finally, high-resolution topographic measurements or processing in situ and/or in the laboratory will be used to characterize the wear and damage of elementary matrix components and individual ceramic grains, in order to determine the damage to CMM constituents ("microscopic wear"). It then becomes possible to select CMM materials, characterize the crusher to feed a technical segmentation of the machines, investigate the link between performance and certain mechanical properties and establish the preliminary bases for the elaboration of simulation and tribological laboratory tests. Our aim is to define a generic methodology for surface morphological characterization to link the tribological behavior of a crusher and thus establish a measure of the performance of a CMM material as a function of the field of use: operating conditions, characteristics of the crushed material (nature, hardness, granulometry).

| Department(s) | Partner(s) | Overall amount |

|---|---|---|

|

330 k€

|

||

| Main support | Rayout | Date(s) |

| Industries | European |

2018 - 2021

|