CrashConnecElecHV

Crash modeling of high-voltage cable connectors in electric vehicles.

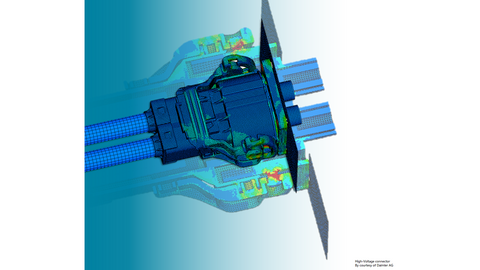

Electric vehicles must comply with several safety regulations. These include the risks of overvoltage and fire due to damage to high-voltage (HV) electrical connectors in road accidents.

In order to meet safety approval criteria and protect HV connectors against breakage, a reliable numerical model is required for industrial-scale crash simulations. This numerical model must effectively reproduce (accurately and within a reasonable computation time) the physical response of the HV connector during a crash. HV connectors used in electric vehicles have a complex geometry and are made up of multi-material assemblies. Consequently, their accurate modeling requires the use of three-dimensional finite element meshes with complex nonlinear behavior models including contact and friction. Unfortunately, this standard modeling entails a significant computational time cost, and is therefore incompatible with the automotive industry's requirements for crash simulation on the scale of a complete vehicle.

.This thesis presents a new methodology for the development of HV connector substitution numerical models specific to electric vehicles. The resulting substitution model is based on the use of basic surface shapes to define the appropriate geometry to be modeled using shell elements, together with a gradient-functionality material model to assess the overall response. Once the replacement HT connector geometry has been generated, the most sensitive physical and material parameters are then identified on the basis of experimental measurements. The stress-state-dependent generalized incremental damage model is implemented with the assumption of plane stresses within a UMAT developed in the LS-DYNA explicit formulation software in order to predict the initiation of connector failure.

The resulting substitute HT connector model was validated, by comparing its solution with those obtained using detailed three-dimensional modeling using a fine mesh, as well as experimental crash tests of components and complete vehicles at Mercedes-Benz. The results obtained, in terms of accurate prediction of overall mechanical response and initiation of connector failure, all achieved within a limited time and computing resources, demonstrate the effectiveness of the proposed methodology

.

| Department(s) | Partner(s) | Overall amount |

|---|---|---|

|

MERCEDES-BENZ Sindelfingen, Germany

|

97,5 k€

|

|

| Main support | Rayout | Date(s) |

|

Industries

|

European |

2018 - 2022

|